I2P Hydroponics

Throughout sophomore year, I worked on the development of a consumer hydroponics product under Georgia Tech’s I2P program. In essence, I2P offers school funding and faculty advisement as groups endeavor to turn commercial Ideas into Prototypes - hence the name I2P.

Origin of the Project

The importance of innovation in the production of food, especially healthy food, cannot be understated. In the 20th century, Norman Borlaug, the Father of the Green Revolution and Nobel Peace Prize winner, is credited with saving over 1 billion people from starvation. I believe that by the end of the 21th century a second Green Revolution will be required to right a population that is both growing in number and growing in unhealthiness. The agricultural industry is responsible for the majority of water usage and the majority of human land usage. In fact, nearly half the habitable land on earth is used for agricultural purposes. Coupled with the large percent of food gone to waste each year and other externalities such as inefficiencies in distribution chains, let alone issues with monoculture, petroleum derived fertilizers, etc… It is all but obvious that the system is not sustainable as is. Additionally, the issues extend into societal problems. Namely, limited access, both physically and economically, to healthy food.

Initial Steps

Before we began on the actual design of our prototype we set up our own DIY hydroponic systems. We used one of the simplest forms of hydroponics, the Kratky Method, which allows the plant(s) to grow in static, nutrient rich water. Beginning with plants hardy to hydro systems, we grow a large variety of herbs and leafy greens. Pictured in Figure 1 are some herb clones cut from plants purchased at the local grocery store.

Figure 1. Herb clones growing in a simple Kratky hydroponics system.

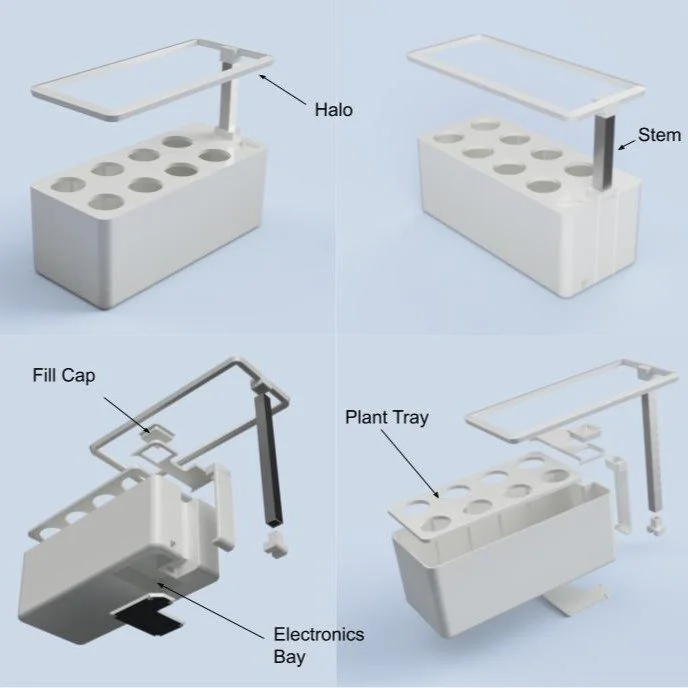

Figure 2. Renderings from prototype CAD.

Design and Prototype

After deliberating with the team on the aesthetic design, I generated an entire model for what would eventually become our prototype. The renderings for that model can be seen in Figure 2 below. We opted for a minimalism-inspired design, with the defining element being the halo shaped light. Additionally, the visible parts and seams are kept to a minimum and the rendings sport simple, two-tone finish of gloss white and bare aluminum. These renderings are held true in the final prototype and use the exact CAD files as can be seen in Figure 6. For a better understanding of the assembly, Figure 2 features exploded views, as well.

The design includes several key features. First the removable plant tray can accommodate up to 8 plants. Each hole fits a standard 2” net pot- a break from comparable devices which attempt to force customers into purchasing proprietary pots. Also, other tray designs were configured to accept various arrays of 1” and 3” standard pots. Thus, offering significant flexibility in what can be grown. The stem of the halo allows for articulation between 4” and 12” above the plant tray’s surface. This is sufficient room to grow most leafy greens and herbs. The removable fill cap allows for simple replenishing of the main tub.

When it came time to print and assemble the prototype, the dimension of the main tub forced it to be printed in two halves. These parts were made in ABS so they could later be chemically welded together using an ABS and acetone slurry. Next, we sanded, printed and painted the tub. The result can be seen in Figure 3. Then, we installed the capacitive sensor and coated the inside with food-grade epoxy. This allowed us to be confident in the safety of the food grown in the prototype.

Figure 4. Additional Printed Parts (left) and Halo post-assembly (right)

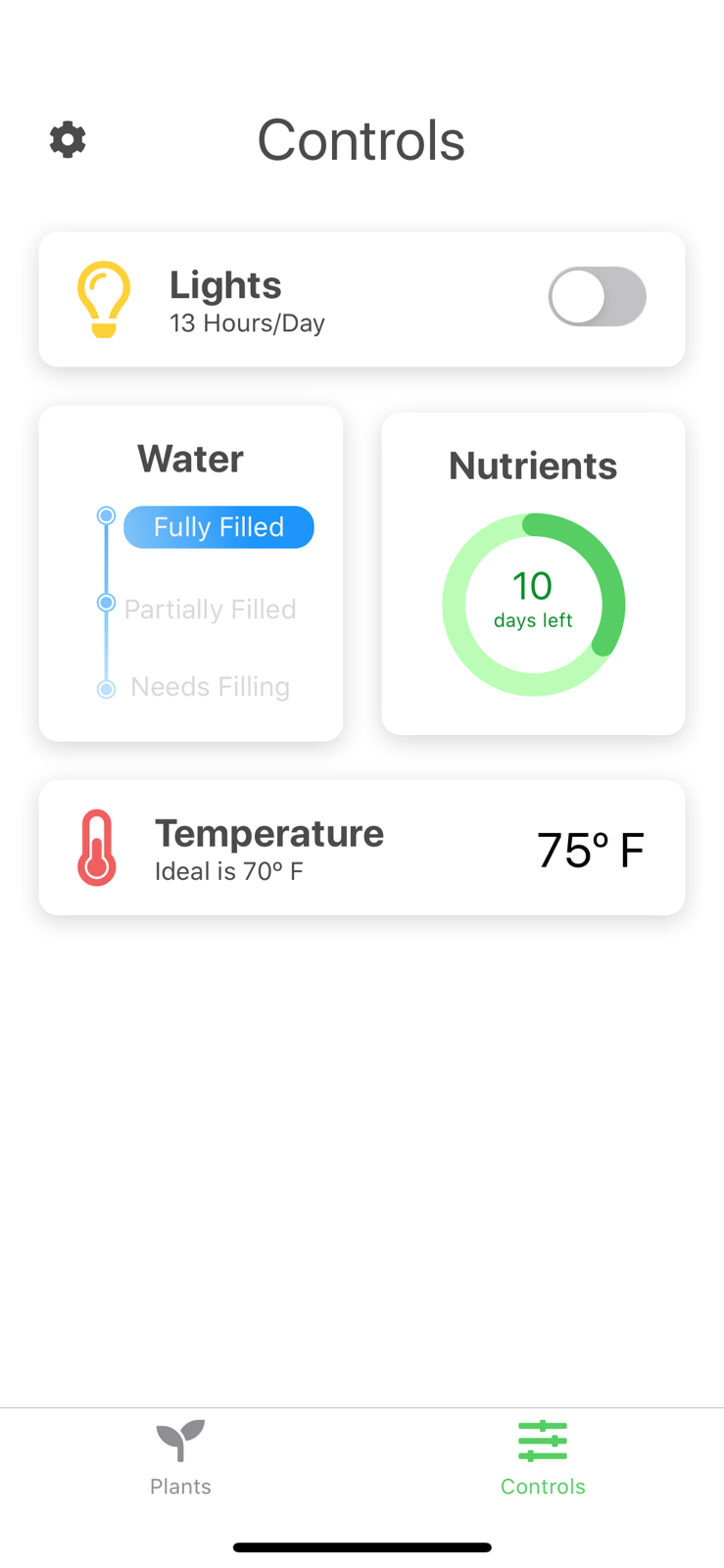

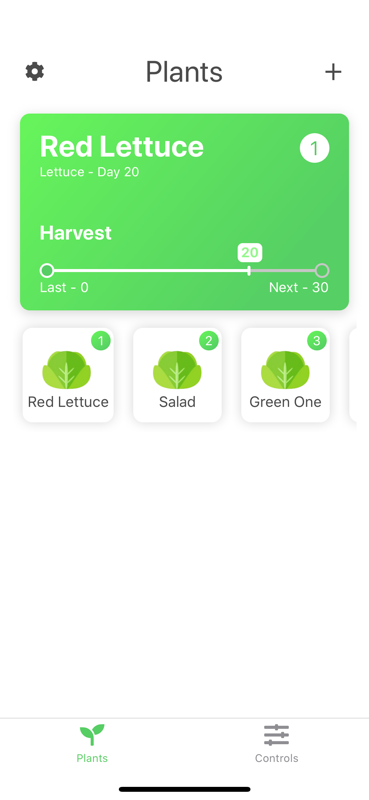

To implement all the functionality previously described, I wrote the code for the microcontroller using the Arduino IDE. For a backend, we used Firebase’s real time database. The Arduino automatically connects to WiFi on startup and connects to Firebase. It pulls light and pump settings from the backend and pushes relevant temperature and water level data. My group-mates constructed a functional iOS app to control the device, screenshots of which are featured below in Figure 5. The app displays data from the system, such as temperature and water level. It allows for the control of lights and pump, and an ability to set schedules for each. Additionally, they were in the process of building out “tips & tricks” features. For example, recommended temperature, light schedule, and estimated date to harvest for specific plants. We believed these features would be integral for a product like this to get wide adoption. There needed to be a gamified aspect to it and people are not inclined to gardening needed to see success with their first use.

Figure 3. Box halves post ABS welding (left) and Box post sanding and painting (right).

The halo was printed in two halves and used the process described previously for the tub. The remaining parts were printed in PLA. They were all sanded, primed and painted. Figure 4 depicts the halo and some of the other parts. Upon completion of the physical assembly, the electronics were installed. The halo carries 20 1 Watt equivalent LEDs, which we estimated to be adequate for the greens and herbs that would be grown in our system.

Figure 5. iOS Application screenshots

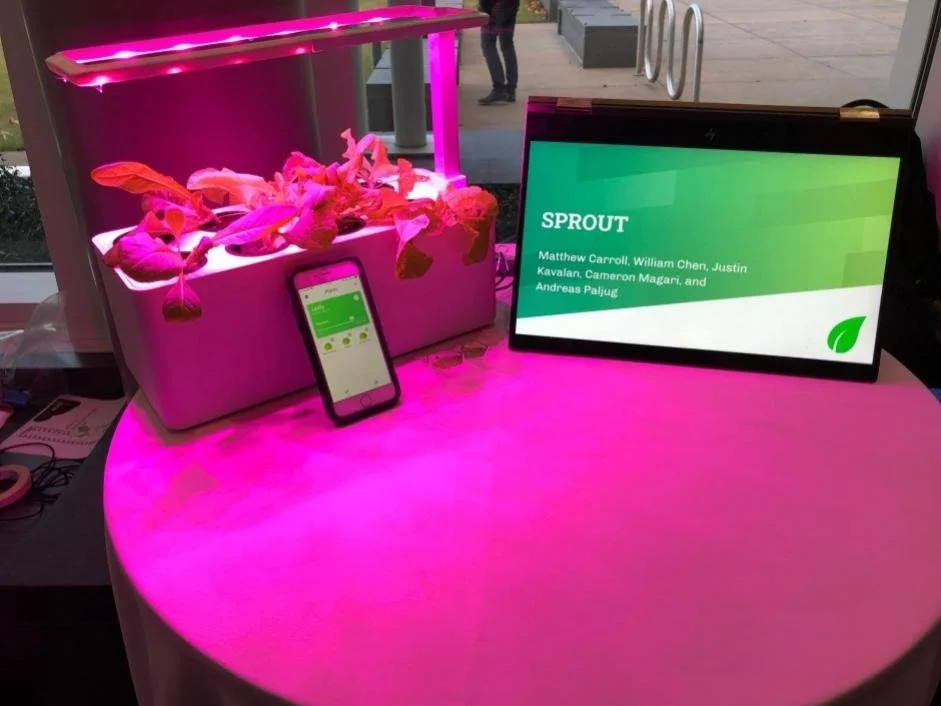

Figure 6. Presentation at Fall 2019 I2P Demo Day.

We concluded our work with a presentation, pictured above in Figure 6. As can be seen, our device was successfully in the process of growing some baby lettuce at the time. We happily ate it after the I2P Demo Day.

Any future iteration will require a redesign of the halo light. Though an interesting concept, it was discovered to have several practical drawbacks. Namely, it did not provide adequate heat sinking for the LEDs- partially because it was 3D printed plastic and partially because of inadequate surface area and mass. Also, covering the gap in the halo will help reduce the apparent brightness of the device while the LEDs are on. This is not as much a problem during daylight hours, but brightness is an issue in lower light environments. Additionally, providing a fully reflective canopy with better spaced LEDs will result in better light coverage for the plants. Future iterations would also opt for different LEDs. Not only are pink full spectrum lights obnoxious, but white full spectrum options with intermittent blue and red LEDs are proving to be a more effective strategy for growers.

From the perspective of the physical build and electronics hardware, obviously many changes in materials and manufacturing would be required to bring a product such as this to production. For instance, the main tube would likely be injection mold using a chemically resistant, food-grade plastic- such as HDPE. All the required circuitry would be fitted on a custom PCB. The device would also be raised slightly on rubber feet, allowing for proper ventilation and cooling of the electronics. Though I knew it at the time, the capacitive sensor is not a long term solution for water level readings because the copper contacts corrode rapidly in the nutrient rich solution. I planned on replacing it with some variety of flow switch. As for operability; future iterations should feature at least some indicator lights and control buttons on the device itself- if not a full control panel.